Nitrite based Corrosion Inhibitors for chilled water systems is a multi-metal corrosion inhibitor based on nitrite and other organic compounds with special yellow metal corrosion inhibitor and anti-scaling agent that helps to prevent scale deposition or also removes adhering loose scale deposits from the heat transfer fluid system.

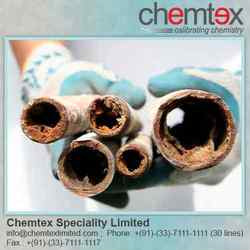

There are several disadvantages for not treating the closed circuit water and in long run it can create troubles for the system operator. The corrosions caused by chiller water, Mono Ethylene Glycol or Brine can cause system leakage in PHE (Plate Heat Exchanger) and AHU (Air Handling Unit). Corrosion can also cause plugging and clogging of tubes and thus reduce flow rate. This will affect the heat transfer rate and will force the system to reduce heat transfer efficiency. This way the system needs regular descaling that incurs shutdowns, leads to additional costing for labor and wastage of time.

“Scale” is a hard deposit of inorganic material on heat transfer surfaces. This is caused by gradual precipitation of mineral particles in water on the surface. During the evaporation of water in a evaporative condenser, pure water vaporizes out and the dissolved solid materials concentrate in the remaining water on the surface. The solids will then settle in pipelines or on heat exchange surfaces, where it frequently solidifies into a relatively soft, amorphous scale.

Next to scale, the next most important concern is the prevention of “corrosion”.

Corrosion is defined as the destruction or loss of metal through chemical or electrochemical reaction with its surrounding environment or material. Mild steel is a most commonly used metal in the cooling water system. But this metal is most susceptible to corrosion. However in some waters and in presence of dissolved gases, such as H2S or NH3, the corrosion to these metals is more severe.

Common problems arising from corrosion are reduction in heat transfer and water flow resulting from a partial or complete blockage of pipes, valves, strainers, etc. Also, excessive wear of moving parts, such as pump, shaft, impeller and mechanical seal, etc. may resist the movement of the equipment. Hence, thermal and energy performance of heat exchange may degrade.

The water treatment in closed system is thus not very critical. Once the initial volume is chemically treated, the quality of the circulating fluid needs to be monitored on a regular basis and additional chemicals added as required to maintain recommended residual concentrations of treatment chemicals.

Most closed-loop water systems use a sodium nitrite based inhibitor for corrosion control and a biocide to prevent biological contamination. These inhibitors will protect both the ferrous and non-ferrous materials in your piping system.

The major advantages of using nitrite based corrosion inhibitor are as follows:-

- Removes dissolved oxygen by converting the nitrite to nitrate.

- Negligible loss of metal or corrosion.

- Excellent heat transferability and flow rate.

- No need of descaling closed circuit equipments.

- Long and extended life of Water without fouling.

Dosage: Nitrite based Corrosion Inhibitor for Water and Glycol Brine is normally fed continuously to the re-circulating closed system by injection dosing pump or dosed to the expansion tank. The amount of Nitrite based Corrosion Inhibitor for Water and Glycol Brine to inhibit corrosion depends on the type of system and plant operating conditions. The specific dosage rates will be specified by the Chemtex's technical representative.

RSS Feed

RSS Feed